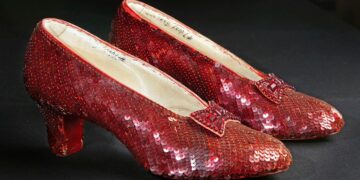

Newly constructed Tre BEV vehicles awaiting cargo to clients from Nikola’s Coolidge, Arizona, plant.

Nikola Inc.

Nikola Inc., which goals to be a pacesetter in battery- and hydrogen-powered heavy vehicles, has begun manufacturing of electrical semis at its new Arizona plant, attending to market at the least a yr forward of Elon Musk’s delayed Tesla Semi.

The corporate’s Coolidge plant, about an hour southeast of its Phoenix headquarters, marked the beginning of business manufacturing of battery-powered Tre vehicles Wednesday at a ceremony joined by Arizona Governor Doug Ducey, who satisfied the corporate to arrange operations within the state. The plant’s preliminary section is a 250,000-square-foot facility that’s constructing only one truck per day at the moment. A 160,000-square-foot enlargement that’s almost full will assist enhance Tre BEV output to 5 per day. A second section of the manufacturing facility opening in 2023 will make Tres powered by hydrogen.

“Now we have been a pre-revenue startup for years, the place every little thing we spent we needed to increase from traders,” Nikola CEO Mark Russell stated on the occasion. “Immediately marks the day once we transition to buyer deliveries. Now we have vehicles that we are able to ship to clients and receives a commission for. We’re now going to be a revenue-producing firm and shall be without end.”

The present low tempo of manufacturing means income shall be modest for the following few quarters, however the truth Nikola made it so far is notable given its chaotic historical past. Not lengthy after the corporate went public Nikola founder Trevor Milton was charged with mendacity to traders concerning the firm’s expertise and market readiness by the Securities and Alternate Fee—prices Milton denies. The corporate agreed to pay a $125 million fantastic to resolve the matter final yr and is searching for to recuperate a lot of that expense from Milton.

Below Russell’s administration, the corporate has tightened relations with industrial companions together with Iveco, which provides the Tre’s chassis, and Bosch, which is working with it on gasoline cells for hydrogen vehicles. Assessments of battery-powered Tres started final yr on the Port of Los Angeles and the corporate is concentrating on gross sales in areas corresponding to Southern California the place the Tre qualifies for an incentive for clean heavy-duty vehicles worth $120,000 per truck. (Every sells for tons of of 1000’s of {dollars} every, although the corporate isn’t sharing detailed pricing.)

With a European-style “day cab” Nikola says the Tre has the longest vary of any electrical semi available on the market, getting 350 miles per cost from its 753 kWh pack. That’s a bigger battery than any of its present opponents, together with electrical fashions from Peterbilt, Kenworth, Freightliner, BYD, Volvo and Lion Electrical.

Nikola CEO Mark Russell on the firm’s Coolidge, Arizona, plant.

Forbes by way of Alan Ohnsman

Musk debuted the Tesla Semi in November 2017 saying the mannequin would journey as much as 500 miles per cost and get to market as early as 2019. Its launch has been pushed again at the least twice since then. This month, on the opening of Tesla’s Giga Austin plant, Musk urged it’d arrive by 2023 after manufacturing of the corporate’s Cybertruck pickup begins. The mannequin was delayed by a choice to concentrate on larger manufacturing of worthwhile automobiles such because the Mannequin 3 and Y and challenges the corporate has had scaling up manufacturing of its new, purpose-built 4680 battery cell.

Massive rigs aren’t the one automobile phase that opponents obtained to sooner than Tesla. Musk’s determination to push again Cybertruck manufacturing to 2023 allowed EV startup Rivian to return to market first with its R1T mannequin. This week Ford additionally started delivery its much-anticipated F-150 Lightning to clients, a battery-powered model of the best-selling U.S. automobile for many years.

Together with making battery-powered Tres in Arizona, Nikola will even make the truck for European clients beginning subsequent yr at a manufacturing line it arrange at an Iveco plant in Ulm, Germany. That’s a reverse of Nikola’s plan a yr in the past. “We initially thought we would begin exporting out of Germany first (to the U.S.) however as issues developed I do not suppose we’ll,” Russell stated. “You do not become profitable by shifting issues throughout oceans.”

Nikola employees assemble a Tre BEV truck on the firm’s Coolidge, Arizona, plant.

Forbes by way of Alan Ohnsman

Nikola’s plant is positioned about 20 minutes from that of fellow EV startup Lucid Motors which lately started constructing high-end electrical Air sedans in Casa Grande, Arizona. Final month, South Korea’s LG Energy Solutions also announced plans to make lithium-ion battery cells beginning in 2024 at a brand new manufacturing facility it’s going to construct in Queen Creek, a Phoenix suburb.

Nikola is utilizing Samsung cells however stated final yr it’s going to additionally supply them from LG, and the proximity of LG’s new plant will give it a bonus. “On a cell foundation we like Samsung, we like LG,” Russell stated. LG “ought to be the most cost effective provide for us–and tremendous high quality.”

Nikola shares fell 2.6% to shut at $7.46 in Nasdaq buying and selling on Wednesday. The corporate is to launch first-quarter outcomes on Might 5.